J-Link Electronics: The first advanced SiC automotive power module production line in Anhui Province has been put into operation

Release time: 2025-02-14

Source: Experts say three and a half generations

The following article is reproduced from the official account of "experts say three and a half generations"

On February 11th, J-Link Electronics achieved another milestone event - successfully holding the "Anhui Province's first advanced process silicon carbide vehicle specification power module production line offline ceremony". With the full production of this production line, J-Link Electronics has completed the key puzzle of the power module motor controller electric drive assembly in the complete closed-loop chain, marking a new stage in the core technology breakthrough and industrialization process of new energy vehicle electric drive systems.

At the ceremony, over a hundred guest representatives from Hefei Economic Development Zone, strategic investors, dozens of leading companies in new energy vehicles and eVTOL aircraft gathered together to witness this historic moment and visit the J-Link Electronics technology exhibition hall and the SiC power module production line intelligent workshop. The attendees highly recognized J-Link Electronics' achievements in process accuracy, quality control standards, and digital management, and expressed their willingness to cooperate to jointly promote the large-scale application of SiC modules in the next generation of vehicle models and models.

J-Link Electronics Technology Exhibition Hall

In addition, in March 2024, J-Link Electronics' 800V silicon carbide high-voltage electric drive assembly production base was successfully put into operation and achieved mass production of products. The launch of the silicon carbide module production line means that J-Link Electronics has the full chain production and supply capacity of silicon carbide power modules, electronic control, and electric drive assemblies. After the new production line is fully constructed and delivered, it can produce 200000 sets of electronic control, 100000 sets of electric drive assemblies, and 1 million power modules annually.

J-Link silicon carbide modules achieve batch delivery and deepen cooperation with multiple automotive companies and eVTOL host factories

On the same day, J-Link Electronics also held a ribbon cutting ceremony for the offline production of SiC power modules. Sun Hongfei, Director of the Investment Promotion Bureau of Hefei Economic Development Zone, Pan Yishan, Head of the School of Modern Industry at Hefei University of Technology and Chairman of Hefei Intelligent Connected Vehicle Innovation Center, Xue Songbai, Chief Technology Officer of Jilv Fly Changkong, Liu Shi, General Manager of Guoyuan Equity Investment Department, Chen Haibin, Procurement Director of Anhui Shenxiang Technology Co., Ltd. and other ribbon cutting guests also delivered speeches, giving high praise to J-Link Electronics' development achievements and cooperation progress in the field of silicon carbide automotive power modules.

Sun Hongfei, Director of the Investment Promotion Bureau of Hefei Economic Development Zone, emphasized that the offline production line of J-Link Electronics' silicon carbide automotive power module is not only a major leap forward for the company's own development, but also an important achievement for Hefei Economic Development Zone in the layout of the new energy vehicle industry chain. It will further enhance the competitiveness of Anhui Province's new energy vehicle core component inspection field and provide strong support for the development of the new energy vehicle industry in the province and even the whole country.

Hefei Economic Development Zone Investment Promotion Bureau - Sun Hongfei

Pan Yishan from Hefei University of Technology believes that the completion and operation of this production line will further enhance Anhui Province's competitiveness in the field of core components for new energy vehicles, and provide strong support for the development of the new energy vehicle industry in the province and even the whole country. At the same time, this also provides new opportunities for deep cooperation between universities and enterprises. In the future, Hefei University of Technology will continue to leverage its research and talent advantages, work hand in hand with J-Link Electronics, and carry out deeper cooperation in fields such as SiC power devices, electric drive systems, and intelligent manufacturing, jointly promoting breakthroughs and innovations in key technologies for new energy vehicles.

Hefei University of Technology - Pan Yishan

Dr. Xue Songbai, Chief Technology Officer of Jiliv Aerospace, first reviewed their cooperation with J-Link Electronics since the beginning of 2023. In just one year, both teams have overcome challenges such as high-precision control and energy efficiency optimization. They started the development of electronic control prototype at the end of 2023 and successfully delivered the first electronic control prototype suitable for low altitude aircraft in April 2024.

Dr. Xue Songbai believes that the completion and operation of this production line is not only a milestone in the vertical integration development of J-Link Electronics' supply chain, but also another boost to the strategic cooperation between Wofei Changkong and J-Link Electronics. J-Link Electronics' SiC power module is expected to become the key core of Wofei Changkong's next-generation flagship model.

Jilvo Flying Long Sky - Xue Songbai

Liu Shi, General Manager of Guoyuan Equity Investment Department, stated that based on J-Link Electronics' outstanding capabilities in the vertical integration of the silicon carbide (SiC) industry chain, the successful large-scale application of core products in mainstream host factories, and the widespread recognition of its product quality by the industry, Guoyuan Equity holds a firm and optimistic attitude towards the long-term development prospects of J-Link Electronics.

The two major "J-Link speeds" demonstrated in the previous cooperation particularly highlight the strength of the enterprise: firstly, Guoyuan Equity achieved significant efficiency in the entire process from project initiation and negotiation on September 23, 2024 to the end of December of the same year, achieving strategic capital injection in just three months; secondly, during the due diligence period, the J-Link Electronics module production line was still in the construction stage, and the enterprise, with its strong engineering implementation capabilities and industrial synergy advantages, quickly completed the production line and achieved mass production goals, fully demonstrating the "Chinese speed" in the field of high-end new energy manufacturing in terms of project execution efficiency.

Guoyuan Equity - Liu Shi

Chen Haibin, the purchasing director of Shenxiang Corporation, revealed that since the strategic cooperation between Shenxiang and J-Link Electronics in 2024, both parties have always driven the localization process of key components for new energy vehicles through technological innovation. At present, the project is progressing efficiently and orderly, and it is expected to achieve bulk supply in the first quarter of 2025. He also stated that this production line is not only a milestone for J-Link Electronics, but also a precise grasp of market demand, a positive response to industry development trends, and will inject strong momentum into the new energy vehicle industry.

Shenxiang Shares - Chen Haibin

According to Chen Zhaoyin, Chairman of J-Link Electronics, J-Link Electronics has received mass production orders and projects for electric drive and electronic control from multiple OEMs in the field of new energy vehicles, and has also established deep cooperation with eVTOL aircraft head OEMs. Its 800V high-voltage silicon carbide process module has been validated and supplied in bulk at multiple OEMs.

Looking ahead to the future, Chen Zhaoyin said, "The achievement of these achievements cannot be separated from the close cooperation of our partners. We will continue to uphold the concept of openness and win-win, work hand in hand with all partners, jointly promote industry technological progress, and promote industrial ecological prosperity

SiC module production line has 4 major advantages, and multiple heavyweight products are grandly released

It is reported that the construction of J-Link Electronics' SiC module production line can be described as "progressing rapidly":

In July 2024, J-Link Electronics officially launched the construction of Anhui's first SiC power module project, with a total investment of over 100 million yuan;

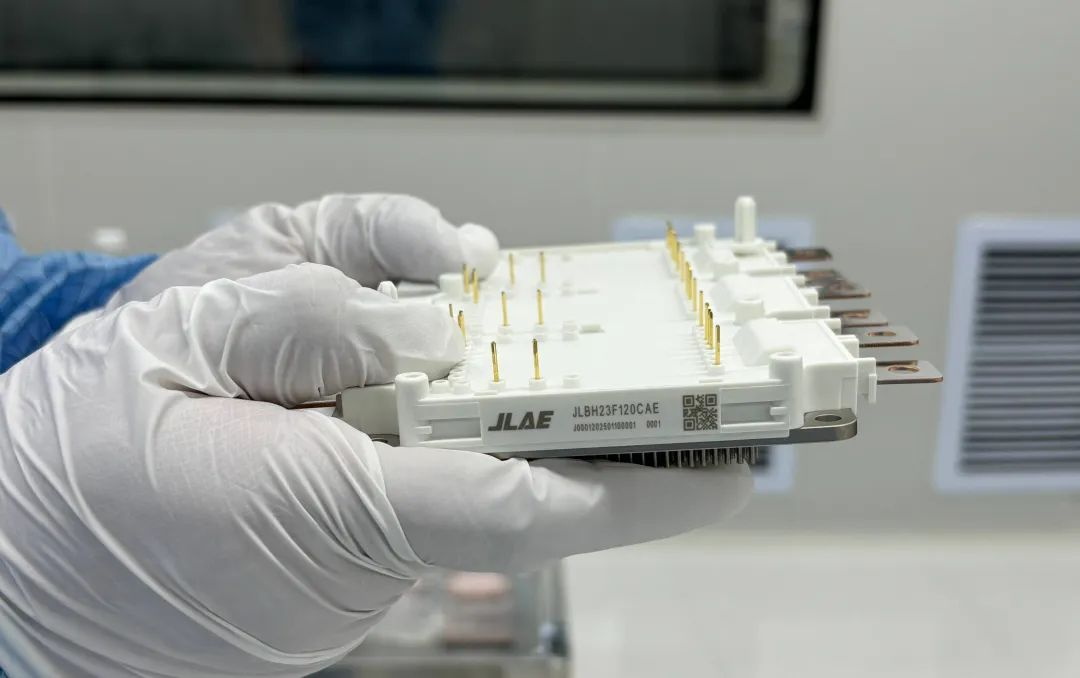

In January 2025, the 001 product "HPD Full Bridge SiC Power Module" A sample of the J-Link Electronics SiC module project was announced to have been successfully launched. The new production line took only six months from the beginning of construction to the production and manufacturing capability;

It is reported that after the comprehensive construction and delivery of the production line, the annual production capacity can reach one million units, which will become an important support for J-Link Electronics' vertical integration layout of the supply chain.

In his speech, Chen Zhaoyin stated that the smooth construction and production of the new SiC automotive power module production line cannot be achieved without the strong support of leaders and partners from various levels of government in Anhui Province and friends from all walks of life. J-Link Electronics has closely collaborated with upstream and downstream partners, greatly promoting the production process. Firstly, it has established deep cooperation with top equipment suppliers, material suppliers, and research institutions both domestically and internationally, successfully overcoming multiple challenges in the research and mass production of silicon carbide power modules; Secondly, the new production line adopts internationally leading packaging equipment and process technology, which not only significantly improves product yield and quality stability, but also reaches the leading level in the industry.

Hefei J-Link Automotive Electronics Co.,Ltd. Chairman Chen Zhaoyin

Chen Zhaoyin stated that as the first advanced process silicon carbide vehicle specification module production line in Anhui Province, J-Link Electronics' new production line embodies the company's latest achievements in technological innovation and process breakthroughs.

Specifically, the SiC module production line launched by J-Link Electronics has four core competitive advantages, which can meet the high reliability requirements of power system core power components in fields such as 800V high-voltage platform vehicles and eVTOL aircraft

One is the original equipment ecosystem: key process equipment adopts internationally leading packaging equipment manufacturers. At the same time, based on the pain points in the SiC power module packaging industry, we jointly develop with industry equipment giants to improve and enhance the equipment in a targeted manner, making it more stable and achieving higher product yield and quality.

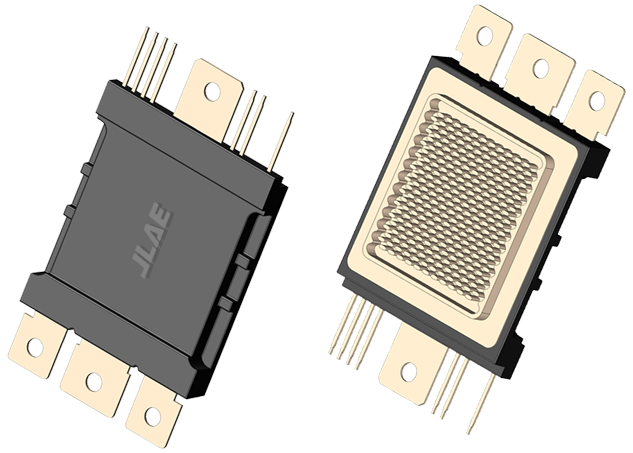

Secondly, it has advanced packaging technology: using pressure sintered silver technology combined with DTS copper wire bonding, it has high reliability and low stray inductance. NTC and heat dissipation bottom plate adopt soldering technology, which simplifies the process flow, does not require cleaning, and is more environmentally friendly.

J-Link Electronics SiC Power Module Production Line

The third is the intelligent quality control system: comprehensive performance testing and reliability evaluation of packaged modules can effectively ensure that product quality and performance meet design requirements.

The fourth is the flexible intelligent manufacturing mode: adopting the "intelligent island+human-machine collaboration" architecture, each process equipment adopts modular design in the form of islands, combining automation and semi automation. While achieving automation, digitization, and intelligence, it can meet the ever-changing product design and growing market demand, and the equipment is more flexible and the utilization rate is higher.

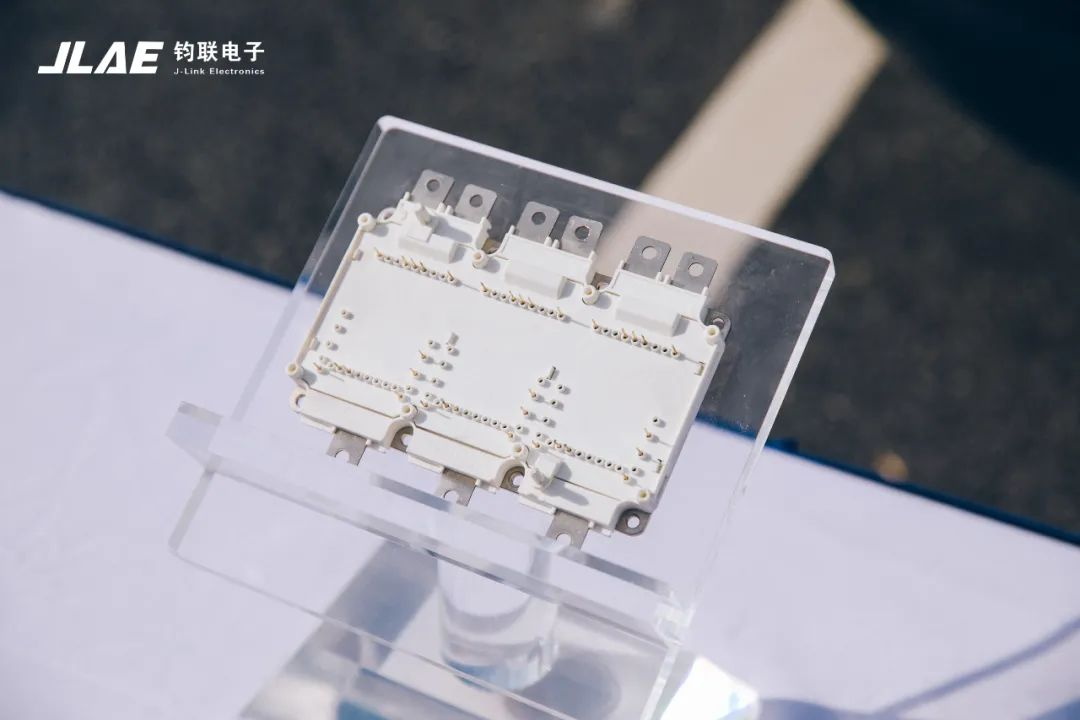

At the event, J-Link Electronics highlighted the launch of two SiC power modules and multiple SiC electronic control and electric drive assembly products:

HPD full bridge SiC power module: Currently, J-Link Electronics' HPD full bridge SiC power module has successfully passed the AQG-324 vehicle grade reliability certification. It adopts a double-sided silver sintering process, effectively reducing on resistance and parasitic inductance, greatly improving power cycle life. The entire product chain adopts a no cleaning process, making the process simpler and more environmentally friendly.

DCM half bridge SiC power module: This product also has unique technical features, using the double-sided silver sintering process of the chip. Compared with similar products, its stray inductance can be within 5nH, significantly reducing the system inductance of the module in the electronic control.

SiC motor controller/800V SiC electric drive assembly: Both types of products use self-developed and self-made SiC power modules. The former has a maximum efficiency of 99.8%, while the latter uses oil cooled flat wire motors, leading the industry in lightweight level at the same power level.

J-Link Electronics has achieved a leading advantage in the industry with its technology and production capacity layout in the fields of silicon carbide power modules and 800V high-voltage electric drive assemblies. Chen Zhaoyin said that in the future, they will take this opportunity to continue to increase research and development investment, deepen technological accumulation, and aspire to become a global leading supplier of silicon carbide process modules and high-voltage electric drive assemblies, providing more efficient and reliable solutions for industries such as new energy vehicles, eVTOL aircraft, and renewable energy.