The first advanced SiC automotive power module production line in Anhui Province has been offline, and J-Link Electronics' "smart hands" have opened a new chapter

Release time: 2025-02-14

Source: New energy in the NE era

The following article is reproduced from the official account of "New Energy in the NE Era":

On February 11th, the offline ceremony of Hefei J-Link Automotive Electronics Co., Ltd. (hereinafter referred to as "J-Link Electronics"), the first advanced process SiC automotive power module production line in Anhui Province, was held in the Anhui Volkswagen Core Parts Industrial Park and achieved complete success.

This is also the first advanced process production line for automotive grade silicon carbide (SiC) power modules based on third-generation semiconductor technology in Anhui Province. This move marks J-Link Electronics' achievement of a technical closed loop in the construction, testing and verification of SiC power module self-developed production line equipment, as well as the full process of the process, and fully mastering the core capabilities of automotive grade SiC modules from packaging design to large-scale manufacturing.

01. Accumulate and make progress, efficiently promote technological breakthroughs

In July 2024, J-Link Electronics invested over 100 million yuan to officially launch the production and construction of the SiC power module project. On January 10, 2025, just six months later, Project 001's product "HPD Full Bridge SiC Power Module" Sample A was successfully taken offline. The SiC automotive power module production line that has been taken offline this time, with "ultra reliability, ultra precision, and ultra environmental protection" as its core competitiveness, directly targets the pain points in the current SiC power module packaging industry.

J-Link Electronics selects internationally leading packaging equipment manufacturers for the selection of key process equipment. Moreover, in response to the pain points in the current SiC power module packaging industry, J-Link Electronics has partnered with industry equipment giants to engage in in-depth research and development cooperation. Through targeted optimization and improvement, the stability of equipment operation has been greatly improved, effectively ensuring high yield and high quality of products.

Moreover, each packaged module must undergo comprehensive and rigorous vehicle performance testing and reliability evaluation by J-Link Electronics. With the intelligent quality control system, we ensure that the quality and performance of each product accurately meet the design requirements.

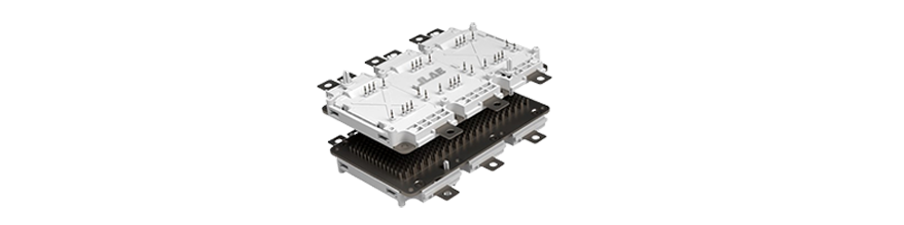

J-Link Electronics SiC Power Module Production Line

In order to meet diverse needs, J-Link Electronics innovatively adopts a "smart island+human-machine collaboration" architecture. Each process equipment adopts a modular design in the form of islands, organically combining automation and semi automation. This mode not only realizes the automation, digitalization and intelligence of production, but also can flexibly respond to the ever-changing product design demand and growing market demand, effectively improving the flexibility and utilization of equipment.

At present, J-Link Electronics' HPD full bridge SiC power module has successfully passed the AQG-324 vehicle grade reliability certification. Adopting double-sided silver sintering technology effectively reduces the on resistance and parasitic inductance, greatly improving the power cycle life. The entire product chain adopts a non cleaning process, which is simpler and more environmentally friendly.

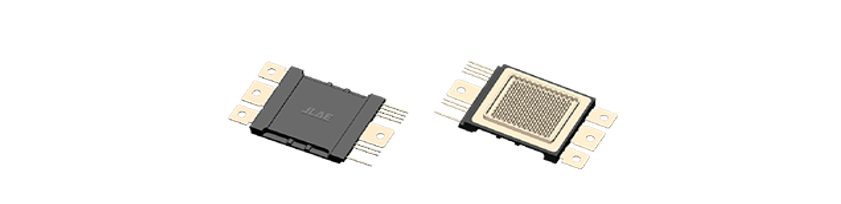

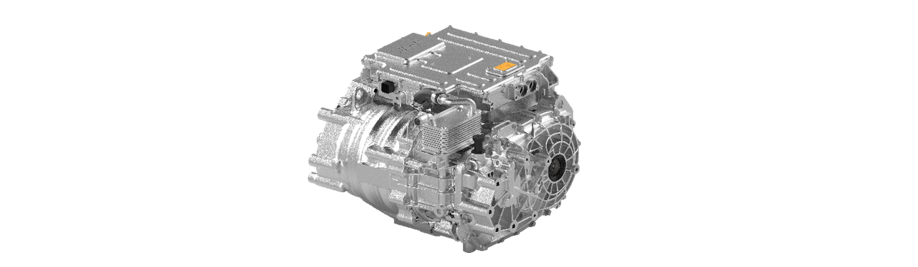

J-Link Electronics HPD Full Bridge SiC Power Module

The internal freewheeling diode has extremely low reverse recovery charge and no threshold voltage conduction characteristics, ensuring the high efficiency and stability of energy conversion. At the same time, the module also has excellent gate oxide layer reliability, strong short-circuit anti avalanche ability, and can operate stably under complex working conditions, providing reliable guarantee for the application of new energy vehicles and related fields.

◎In addition, J-Link Electronics' DCM half bridge SiC power module also has unique technological highlights. Using the same double-sided silver sintering process for the chip, compared to similar products, its stray inductance can be reduced to within 5nH, significantly reducing the system noise of the module in the electronic control.

J-Link Electronics DCM Half Bridge SiC Power Module

In terms of packaging, the use of vacuum plastic sealing technology greatly enhances the environmental adaptability of the product, ensuring stable operation in harsh environments such as high temperature, humidity, and dust. At the same time, the half bridge replacement operation is more convenient, and its combination flexibility is higher in different circuit combinations, which can better meet diverse usage needs and provide more advantageous solutions for various application scenarios.

02. Technology leads, diversified products bloom comprehensively

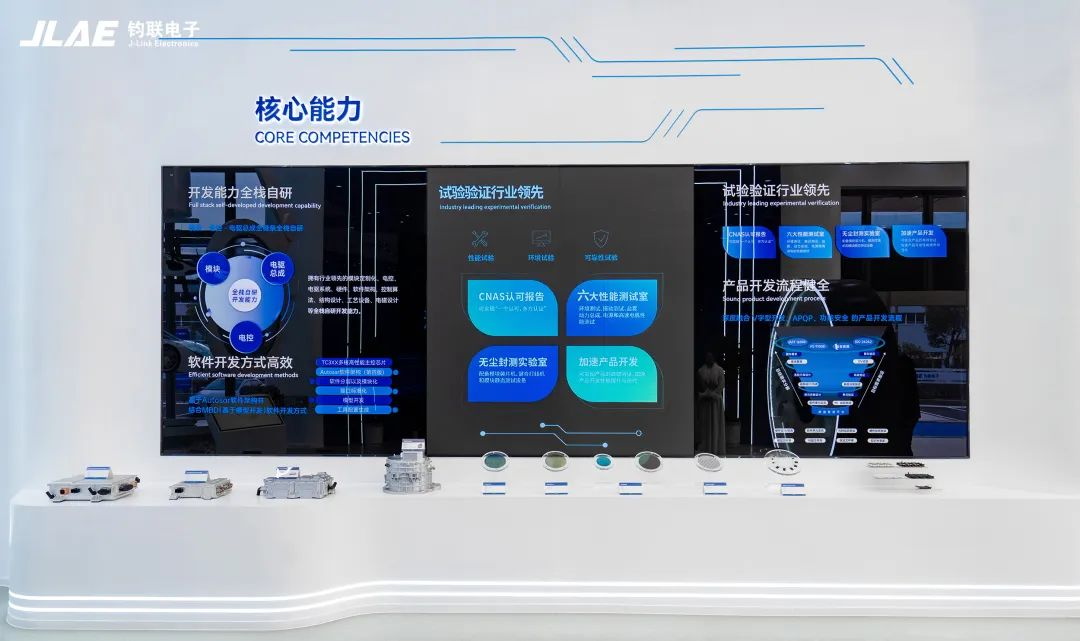

In terms of supply chain, J-Link Electronics has always adhered to the vertical integration layout policy of the supply chain, and has the ability to independently research the SiC power module motor controller electric drive assembly for the entire chain and stack. It also has a certain degree of autonomy in the supply of key raw materials, which can better control the cost and quality, and ensure the stable production of SiC power modules and other products.

Image source: J-Link Electronics

In terms of products, J-Link Electronics has always adhered to a diversified product matrix and has been striving for breakthroughs. In terms of motor controller, we have completed the development of 800V high-voltage SiC motor controller, 800V multi fusion SiC power domain controller, range extender generator controller, DHT dual electronic control and other products, and achieved batch installation.

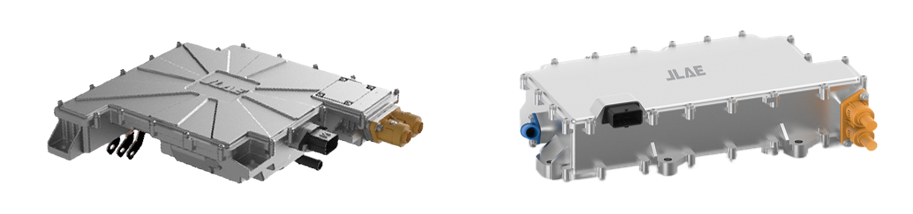

■ Left: 800V High Voltage SiC Motor Controller ■ Right: DHT dual motor controller

In terms of electric drive assemblies, in March 2024, the 800V silicon carbide three in one electric drive assembly project with an annual output of 100000 sets will be mass-produced. This product adopts oil cooled flat wire motor technology and full silicon carbide power devices. The maximum working voltage can reach 900V, and the maximum speed of the electric drive system can reach 21000rpm. The system assembly weighs only 77kg, and the integrated BOOST boost function can achieve 7-minute battery SOC charging from 30% to 80%.

200-250kW 800V silicon carbide electric drive assembly

J-Link Electronics' products are not only used in the field of new energy vehicles, but also in the eVTOL aircraft market. It is reported that its eVTOL SiC motor controller has been selected by top customers and completed prototype delivery. In the past few years, enterprises have collaborated with Jianghuai deepway、 Wofei Changkong and other enterprises have reached strategic cooperation and achieved mass delivery. At the same time, J-Link Electronics has actively connected with leading enterprises such as Chery, Volkswagen, Geely, Changan, BYD, etc., continuously expanding market share and enhancing brand influence.

J-Link Electronics' SiC power module production line, with its core competitive advantage, can fully meet the high reliability requirements of power system core power components in fields such as 800V high-voltage platform vehicles and eVTOL aircraft. After the comprehensive construction and delivery of the production line, the annual production capacity can reach one million units, which will become a powerful booster for the vertical integration layout of J-Link Electronics' supply chain and inject strong impetus into the development of the industry.